Head

Prof. Dr. Volker Sieber

Chair of Chemistry of Biogenic Resources

- Rector TUMCS

- Head of Chair

- Phone:

- +49 9421 187-300

- Email:

- sieber@tum.de

Office

Anna Kronewald

Chair of Chemistry of Biogenic Resources

- Team Assistant

- Phone:

- +49 9421 187-301

- Email:

- anna.kronewald@tum.de

Eva Groll

Chair of Chemistry of Biogenic Resources

- Team Assistant

- Phone:

- +49 9421 187-307

- Email:

- eva.groll@tum.de

Research Assistants and Doctoral Students

Dr.-Ing. Ammar Al-Shameri

Chair of Chemistry of Biogenic Resources

- Postdoctoral Researcher & Groupleader

- Phone:

- +49 9421 187-322

- Email:

- a.al-shameri@tum.de

Dr. Sara Arana Pena

Chair of Chemistry of Biogenic Resources

- Postdoctoral Researcher, Groupleader

- Phone:

- +49 9421 187-343

- Email:

- sara.arana@tum.de

Dr. Alexander Fuchs

Chair of Chemistry of Biogenic Resources

- Postdoctoral Researcher

- Phone:

- +49 9421 187-320

- Email:

- alex.fuchs@tum.de

Antonio Giustino, M.Sc.

Chair of Chemistry of Biogenic Resources

- Doctoral Candidate

- Phone:

- +49 9421 187-305

- Email:

- antonio.giustino@tum.de

Jan Grundheber, M.Sc.

Chair of Chemistry of Biogenic Resources

- Doctoral Candidate

- Phone:

- +49 9421 187-330

- Email:

- jan.grundheber@tum.de

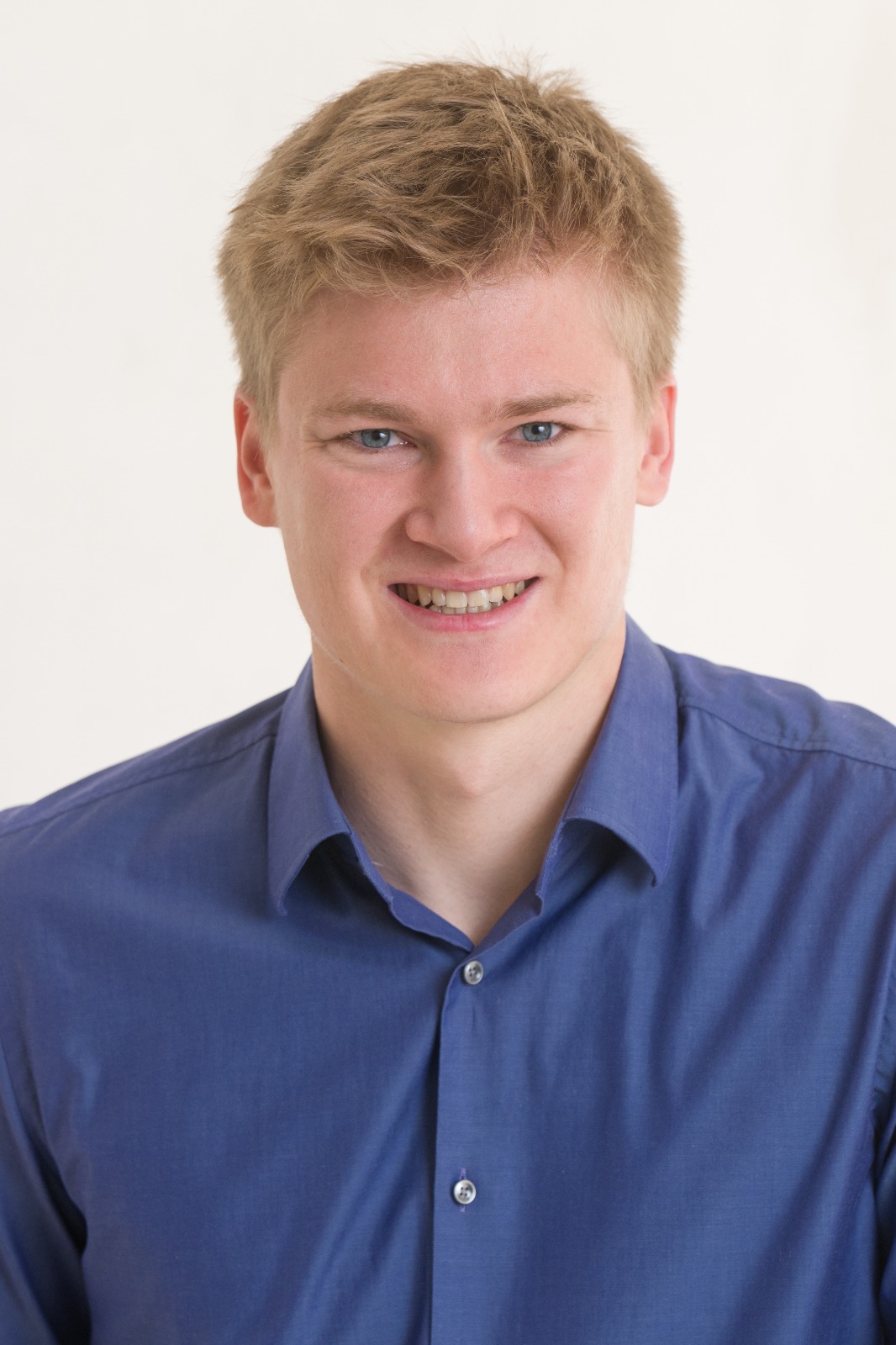

Niklas Hofer, M.Sc.

Chair of Chemistry of Biogenic Resources

- Doctoral Candidate

- Phone:

- +49 9421 187-323

- Email:

- niklas.hofer@tum.de

Dr. Thomas Kinateder

Chair of Chemistry of Biogenic Resources

- Postdoctoral Researcher

- Phone:

- +49 9421 187-331

- Email:

- Thomas.kinateder@tum.de

Tobias Köllen, M.Sc.

Chair of Chemistry of Biogenic Resources

- Doctoral Candidate

- Phone:

- +49 89 289-54209

- Email:

- tobias.koellen@tum.de

TUM Catalytic Research Center

Ernst-Otto-Fischer-Straße 1

85748 Garching

Germany

Room: 2018

Viktoria Lehmann, M.Sc.

Chair of Chemistry of Biogenic Resources

- Doctoral Candidate

- Phone:

- +49 9421 187-325

- Email:

- viktoria.lehmann@tum.de

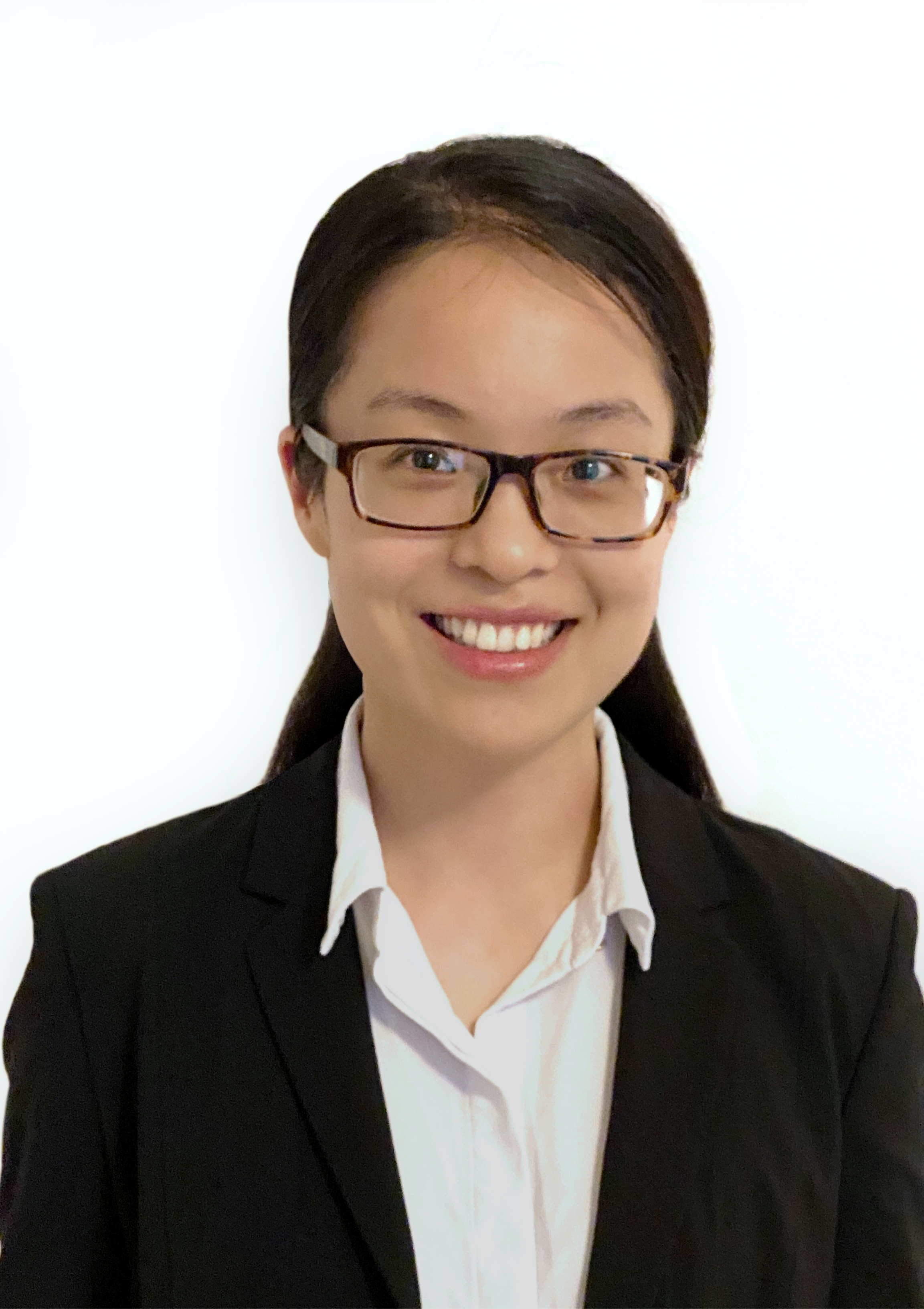

Dr. Yajing Liu

Chair of Chemistry of Biogenic Resources

- Postdoctoral Researcher, Research Assistant

- Phone:

- +49 9421 187-333

- Email:

- yajing.liu@tum.de

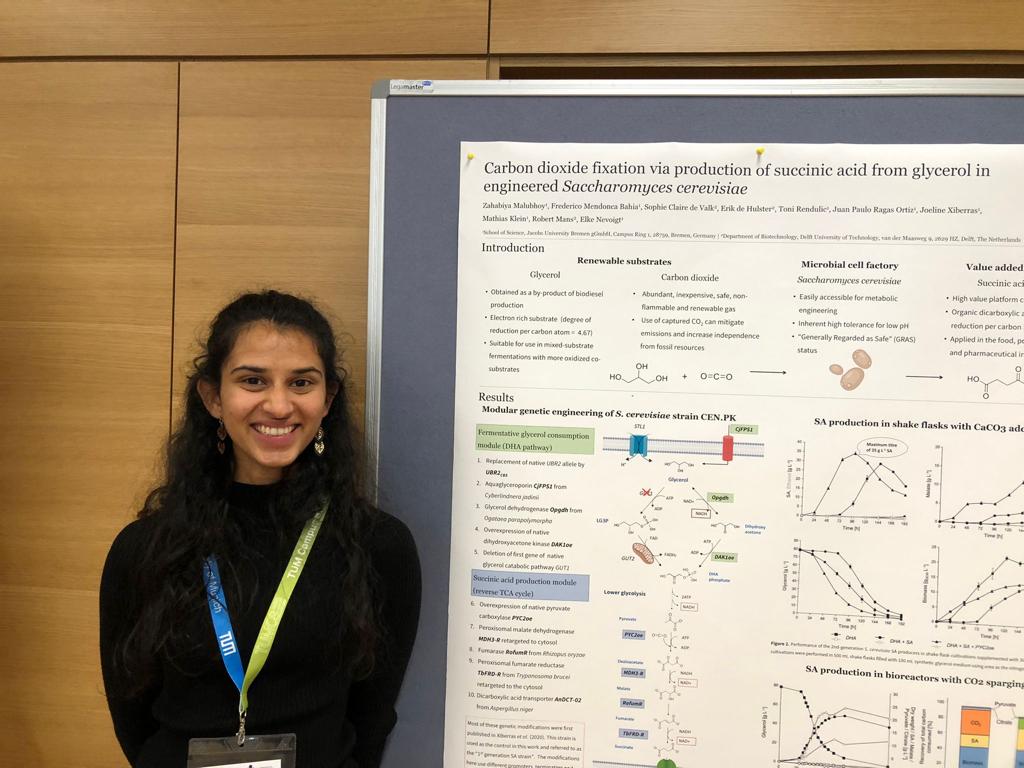

Zahabbyia Malubhoy, M.Sc.

Chair of Chemistry of Biogenic Resources

- Doctoral Candidate

- Phone:

- +49 9421 187-345

- Email:

- z.malubhoy@tum.de

TUM Catalytic Research Center

Ernst-Otto-Fischer-Straße 1

85748 Garching

Germany

Matea Marosevic, M.Sc.

Chair of Chemistry of Biogenic Resources

- Doctoral Candidate

- Phone:

- +49 9421 187-313

- Email:

- matea.marosevic@tum.de

Franka Matena, M.Sc.

Chair of Chemistry of Biogenic Resources

- Doctoral Candidate

- Phone:

- +49 9421 187-324

Marcel Mayer, M.Sc.

Chair of Chemistry of Biogenic Resources

- Doctoral Candidate

- Phone:

- +49 9421 187-316

- Email:

- ma.mayer@tum.de

Tobias Ostertag, M.Sc.

Chair of Chemistry of Biogenic Resources

- Doctoral Candidate

- Phone:

- +49 9421 187-315

- Email:

- tobias.ostertag@tum.de

Dr. Enrique Raga Carbajal

Chair of Chemistry of Biogenic Resources

- Postdoctoral Researcher, Groupleader

- Phone:

- +49 9421 187-306

- Email:

- enrique.raga@tum.de

Maximiliane Rau, M.Sc.

Chair of Chemistry of Biogenic Resources

- Doctoral Candidate

- Phone:

- +49 9421 187-287

- Email:

- maximiliane.rau@tum.de

Dennis Romeis, M.Sc.

Chair of Chemistry of Biogenic Resources

- Doctoral Candidate

- Phone:

- +49 9421 187-178

- Email:

- dennis.romeis@tum.de

Dr. Broder Rühmann

Chair of Chemistry of Biogenic Resources

- Postdoc & Groupleader

- Phone:

- +49 9421 187-332

- Email:

- broder.ruehmann@tum.de

Jonathan Scheerer, M.Sc.

Chair of Chemistry of Biogenic Resources

- Doctoral Candidate

- Phone:

- +49 9421 187-349

- Email:

- jonathan.scheerer@tum.de

Dr. Doris Schieder

Chair of Chemistry of Biogenic Resources

- Postdoc & Groupleader

- Phone:

- +49 9421 187-303

- Email:

- doris.schieder@tum.de

Dr. Amelie Skopp

Chair of Chemistry of Biogenic Resources

- Research Fellow

- Groupleader

- Phone:

- +49 9421 187-345

- Email:

- amelie.skopp@tum.de

TUM Campus Straubing

Schulgasse 16

94315 Straubing

Lianqing Tong

Chair of Chemistry of Biogenic Resources

- Doctoral Candidate

- Phone:

- +49 89 289-54209

- Email:

- l.tong@tum.de

TUM Catalytic Research Center

Ernst-Otto-Fischer-Straße 1

85748 Garching

Germany

Room: 2018

Technical Personnel

Dipl.-Ing. (FH) Manuel Döring

Chair of Chemistry of Biogenic Resources

- Technical Assistant

- Phone:

- +49 9421 187-319

- Email:

- manuel.doering@tum.de

Magdalena Haslbeck

Chair of Chemistry of Biogenic Resources

- Technical Assistant

- Phone:

- +49 9421 187-327

- Email:

- m.haslbeck@tum.de

Dipl.-Ing. (FH) Anja Schmidt

Chair of Chemistry of Biogenic Resources

- Technical Assistant

- Phone:

- +49 9421 187-336

- Email:

- a.v.schmidt@tum.de

Kai Stirnweiß

Chair of Chemistry of Biogenic Resources

- Technical Assistant

- Phone:

- +49 9421 187-337

- Email:

- kai.stirnweiss@tum.de

Lena Würstl

Chair of Chemistry of Biogenic Resources

- Technical Asistant

- Phone:

- +49 9421 187-326

- Email:

- lena.wuerstl@tum.de

Alumni

| Prof. Dr.-Ing. Jochen Schmid |

| Daniel Bauer |

| Dominik Schwarz |

| Dr. Herbert Goldinger |

| Dr. Claudia Nowak |

| Dr. Steven Koenig |

| Dr. Tobias Gmelch |

| Dr. Nadine Sperl |

| Dr. Michael Loscar |

| Dr. Jose Guillermo Ortiz Tena |

| Dr. Ulrike Obst |

| Dr. Steffen Roth |

| Janine Simon |

| Lisa Steiner |

| Janine Huber |

| Karola Wiesmüller |

| Dr. Fabian Steffler |

| Dr. Marius Rütering |

| Dr. Irina Funk |

| Dr. Hendrik Hohagen |

| Alfiya Wohn |

| Andre Pick |

| Qianqin Zhu |

| Dr. Nina Rimmel |

| Dr. Nadine Borst |

| Dr. Jörg Carsten |

| Ioannis Zachos |

| Dr. Paul Stockmann |

| Dr.-Ing. Sumanth Ranganathan |

| Scott Bottoms |

| Dr. Joseph Sperl |

| Dr. Edilberto Medina Cabrera |

| Dr. Moritz Gansbiller |

| Dr. Robert Genth |

| Dr. Samed Güner |

| Dr. Korbinian Sinzinger |

| Dr. Barbara Beer |

| Dr. Benjamin Begander |

| Dr. Samuel Sutiono |

| Dr. Christoph Schilling |

| Dr. Torben Hüsing |

| Dr. Johanna Radomski |

| Mathilde Steinmaßl |

| Dr. Okke Melse |

| Matthias Steiger |

| Tatjana Laudage |

| Alexander Benson |

| Dr.-Ing. Tristan Rath |

| Dr. Luca Schmermund |

| Dr. Vivian Willers |

| Dr. Mariko Teshima |

| Masoud Babakhani |

| Ernesto Rodriguez |

| Eleonora Fornoni |

| Dr. Enrico Hupfeld |

| Amir Hossein Abbas Nia |

| Zinnia Dsouza |

| Jan-Simon Friedrichs |

| Dominik Siebert |

| Mayla Schulz |

| Kathrin Hörnschemeyer |

- Prof. Dr.-Ing. Jochen Schmid

- Daniel Bauer

- Dominik Schwarz

- Dr. Herbert Goldinger

- Dr. Claudia Nowak

- Dr. Steven Koenig

- Dr. Tobias Gmelch

- Dr. Nadine Sperl

- Dr. Michael Loscar

- Dr. Jose Guillermo Ortiz Tena

- Dr. Ulrike Obst

- Dr. Steffen Roth

- Janine Simon

- Lisa Steiner

- Janine Huber

- Karola Wiesmüller

- Dr. Fabian Steffler

- Dr. Marius Rütering

- Dr. Irina Funk

- Dr. Hendrik Hohagen

- Alfiya Wohn

- Andre Pick

- Qianqin Zhu

- Dr. Nina Rimmel

- Dr. Nadine Borst

- Dr. Jörg Carsten

- Ioannis Zachos

- Dr. Paul Stockmann

- Dr.-Ing. Sumanth Ranganathan

- Scott Bottoms

- Dr. Joseph Sperl

- Dr. Edilberto Medina Cabrera

- Dr. Moritz Gansbiller

- Dr. Robert Genth

- Dr. Samed Güner

- Dr. Korbinian Sinzinger

- Dr. Barbara Beer

- Dr. Benjamin Begander

- Dr. Samuel Sutiono

- Dr. Christoph Schilling

- Dr. Torben Hüsing

- Dr. Johanna Radomski

- Mathilde Steinmaßl

- Dr. Okke Melse

- Matthias Steiger

- Tatjana Laudage

- Alexander Benson

- Dr.-Ing. Tristan Rath

- Dr. Luca Schmermund

- Dr. Vivian Willers

- Dr. Mariko Teshima

- Masoud Babakhani

- Ernesto Rodriguez

- Eleonora Fornoni

- Dr. Enrico Hupfeld

- Amir Hossein Abbas Nia

- Zinnia Dsouza

- Jan-Simon Friedrichs

- Dominik Siebert

- Mayla Schulz

- Kathrin Hörnschemeyer