Biogenic Raw materials contain a large number of different substances. In order to obtain basic materials from them for future industrial use, the raw materials must be suitably processed. This includes pre-treatment, fractionation and separation of the desired ingredients. These can then be further converted via chemical or biotechnological methods in order to substitute petrochemical products or synthesise new functional substance.

The area of “Biomass Digestion & Fermentation” conducts research on the targeted and customised processing of biogenic raw materials and residues, as well as on the development of biobased processes for the further conversion of ingredients into valuable basic materials for the chemical industry or into energy sources.

Main areas of research are:

- Biorefinery systems for the most complete and sustainable use of raw materials.

- Digestion and fractionation of lignocellulose-containing biomass such as straw, grasses and wood.

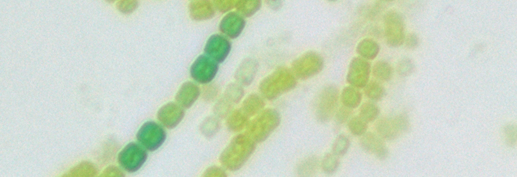

- Digestion and fractionation of microalgae

- Mechanical, physico-chemical (thermal hydrolysis) and chemical digestion processes in combination with enzymatic processes

- Bioconversion of saccharides in lignocellulosic hydrolysates

- Biogas technology: microbiological and enzymatic hydrolysis, optimisation of process biology

Development of fermentation processes, e.g. for the biosynthesis of alcohols, diols, carboxylic acids, esters and biobased polymers.

In addition to the molecular optimisation of biotechnological processes at the enzyme or cell level, there is also the scaling and process optimisation. Bioprocess engineering helps to replace conventional chemical processes, especially in the utilisation of biogenic raw materials, by producing a variety of valuable substances. In addition to purely enzyme-based processes, fermentative processes, which enable the production of substances with the help of microorganisms, are still essential today.

The research area “Fermentative Processes” is concerned with the development of these processes for the targeted production and processing of valuable products.

In particular, the integration of residual material flows is of central importance and an important aspect in terms of circular economic cycles.

In order to ensure economic production or to compete with conventional processes, processes must be continuously optimised and adapted to the latest biological findings.